Maintaining operational electric gates during winter is important, particularly in varied climates like those in Tennessee, Georgia, and Florida, where harsh elements may affect components not properly covered, your gate could freeze, and inclement weather causes rust. We focus on providing solutions that keep your gates functioning smoothly, preventing downtime and saving you on repair costs.

Automatic Gate Functionality in Diverse Climates

Cold weather brings unique challenges, requiring specific strategies for different regions. In Tennessee’s freezing temperatures, effective snow management and insulation are vital. In contrast, Georgia’s humid climate demands robust waterproofing and sealing. Meanwhile, Florida’s subtropical conditions necessitate focused rust prevention and moisture control.

Understanding region-specific challenges, appropriate measures can be taken to improve the longevity and functionality of electric gates in diverse climates:

Cold Weather Challenges

- Snow Accumulation: Heavy snowfall can obstruct gate movement and sensors.

- Freezing Mechanisms: Cold temperatures may cause mechanical parts to freeze and malfunction.

- Insulation Needs: Lack of proper insulation can lead to electrical components malfunctioning in extreme cold.

Humid Climate Concerns

- Moisture Damage: High humidity can lead to short-circuiting of electrical components.

- Rust and Corrosion: Persistent moisture can cause rusting of metal parts, affecting gate functionality.

- Seal Deterioration: Humidity can degrade seals and lubricants, leading to increased wear and tear.

Subtropical Climate Issues

- Rust Prevention: High humidity and salt air can accelerate rusting, especially in coastal areas.

- Moisture Control: Frequent rain and damp conditions can affect electrical systems and sensors.

- Heat Impact: Prolonged exposure to high temperatures can affect the durability and operation of gate components, which impacts the ability of the equipment to withstand storms and other inclement weather.

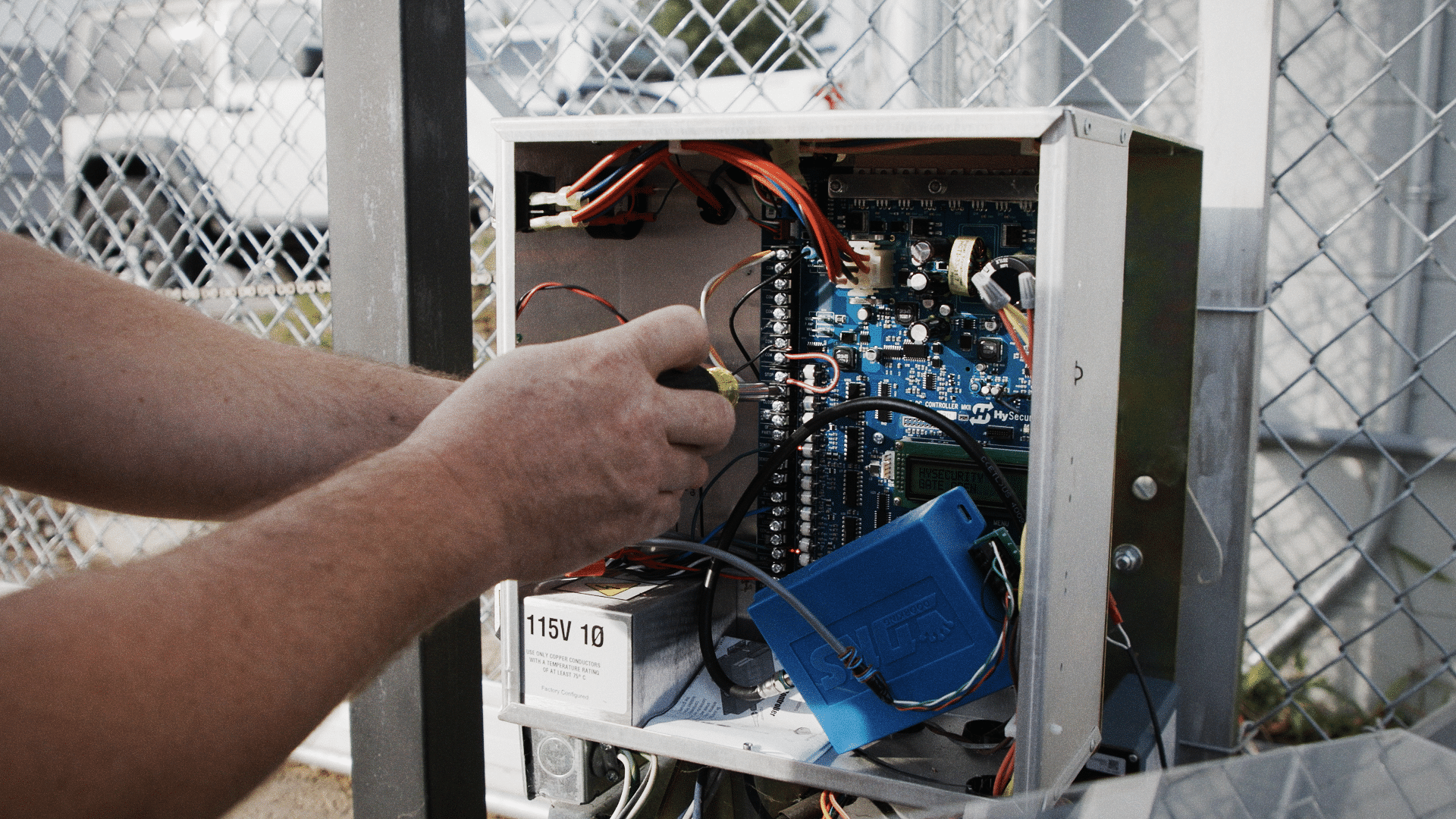

How to Prepare Electric Gates for Winter

To get your gates ready for the winter, consider these tips and recommendations:

Weatherproofing Seals: Check and replace worn-out weather seals around gate openings. This helps prevent moisture and cold air from affecting the gate’s operation, especially in regions with heavy rainfall or snow.

Weatherproofing Seals: Check and replace worn-out weather seals around gate openings. This helps prevent moisture and cold air from affecting the gate’s operation, especially in regions with heavy rainfall or snow.- Clearing Debris and Snow: Regularly clear away leaves, snow, and ice from the gates and surrounding areas. Accumulated debris can hinder gate movement and sensor functionality, more so in Tennessee’s occasional snowy conditions.

- Heating Cables for Critical Components: In extremely cold regions like Tennessee, consider installing heating cables around critical mechanical components. This prevents freezing and maintains smooth operation even in sub-zero temperatures.

- Moisture Absorbers and Desiccants: In humid areas like Georgia and Florida, use moisture absorbers or desiccants near electrical components to reduce the risk of moisture-related damage.

- Regular Lubrication: Apply high-quality lubricants suitable for colder temperatures to all moving parts. This prevents them from seizing up due to cold and moisture, a common issue in varied climates.

- Surge Protection: Implement surge protection measures for the electrical components of the gate. Winter storms, especially in areas like Tennessee, can cause power surges that may damage the gate’s electrical system.

- Professional Assessment: Consider having a professional assess your gate system before the onset of winter. Professionals are able to provide experienced advice and easily identify potential issues specific to your region’s climate.

Seasonal Gate Protection with Guardian

Let us help you navigate the challenges of winterizing your electric gates. Our experience spans across diverse climates. Whether you’re in Tennessee, Georgia, or Florida, make sure your gates are prepared for the winter months.

Contact Guardian Access Solutions for customized advice and solutions, and confidently welcome winter, knowing your gates are in expert hands.